Failure Mode and Effects Analysis - FMEA Training Course

DURATION

1 dayCPD

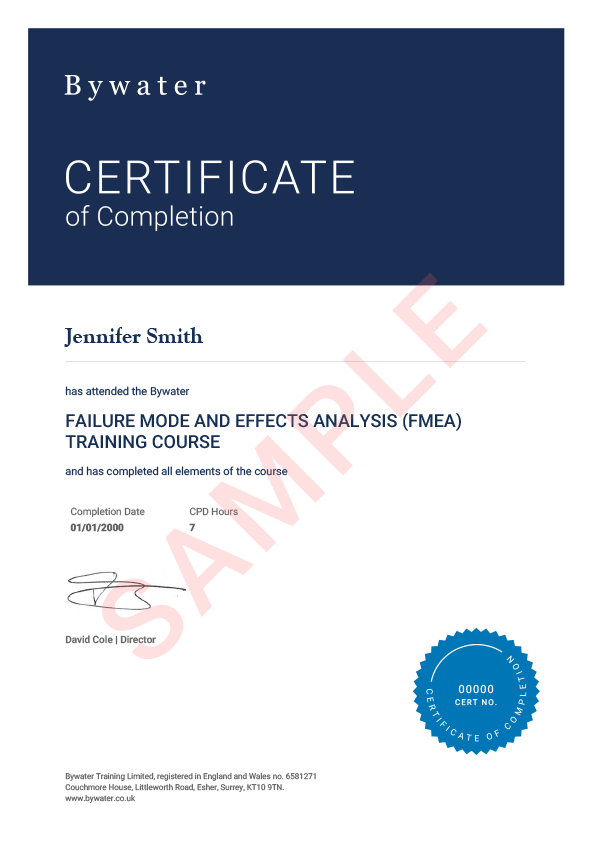

Equivalent to 7 hoursCERTIFICATES

All delegates will receive a certificate on completion.DELIVERY OPTIONS

Gain an understanding of the principles behind Failure Mode and Effects Analysis (FMEA) techniques and how they can be applied at each stage of product and process development by attending this Failure Mode and Effects Analysis – FMEA training course.

Upon completion of the course, delegates will have a basic knowledge of the FMEA methodology and how to apply it to improve product and process design, with the aim of identifying, controlling and eliminating the risk of failure.

- product developers involved in developing new product introduction strategies and those concerned with ‘time-to-market’

- manufacturing and engineering managers who need to improve manufacturing capability, predict initial product yield and improve cross-functional technical communications

- design engineers responsible for new product design and introduction who need to improve customer definition and manufacturing feedback

- quality/reliability managers and engineers who want to facilitate an awareness and application of these tools within their organisation

- process engineers who will be involved in formulating the manufacturing control plan

Additional core tools courses include Introduction to APQP and PPAP, Measurement Systems Analysis (MSA), and Statistical Process Control (SPC).

Discounts are available for multiple bookings. Book 2 Core Tools training courses together for a £100 discount.

Book our Core Tools Package, providing training on all 5 tools across 4 days, and save significantly on the cost of booking the courses individually.

- the business need for FMEA in product and process design

- types of FMEA – system, design, process and machinery

- FMEA methodology and defining:

- customer’s expectations and requirements

- potential failure modes

- consequences of failure and identifying causes

- methods of detection and prevention

- assessing severity

- evaluating the ‘risk’ and prioritising areas for improvement

- implementing corrective actions in product and process design

- risk reduction strategies

- case studies:

- product design FMEA

- process FMEA

The connections between FMEAs and design validation/production control plans and other quality management tools will be explained during the course.

- WELCOME AND INTRODUCTIONS

- Module 1 Introduction and Overview of FMEA

- Module 2 FMEA Purpose & Structure

- Module 3 FMEA Teams

- Module 4 FMEA Scope

- Module 5 FMEA Creation

- Module 6 Process FMEA

- CLOSE

- identifying the requirements and expectations for the product or process

- identifying and defining potential failure modes

- developing an effective control plan that will reduce the risk of product failure

- identifying and assessing the potential effects of failure on internal processes, supply chain partners and end users

To recognise their new knowledge and skills in FMEA, delegates who attend the full course will receive a certificate of completion.

Upcoming course dates

Failure Mode & Effects Analysis is an approach to identifying possible failures in design and manufacture and minimising the risk of failure occurring.

FMEA was first used by NASA in the 1960s for the Apollo space missions, before being adopted by the Navy, and then by the automotive industry in the late 1970s. Today a wide range of industries are taking advantage of the benefits of FMEA.

FMEA is used to identify, control and eliminate the risk of failure by improving:

- system design and specification

- product design and validation process

- production process and control plan

Risk is reduced by implementing

- changes in the product design or production methods

- controls to prevent or detect potential failure modes

This 1-day course is a blend of expert tutoring and interactive workshops and discussions. By working through the performance of FMEA techniques you will be able to reinforce your learning while still in the classroom. This applies whether you are attending a face-to-face class or joining online in our Virtual Classroom.

The Core Tools training courses are independent while also being complementary. That means you can choose which courses to attend and in which order.

If you wish to learn 2 or more Core Tools, we recommend you book these courses at the same time and enjoy a discount. If you wish to learn all 5 Core Tools, then our Core Tools Package will give you even greater cost benefits.

Yes, we will send you a certificate of attendance after the course has ended. This will provide you with evidence of your extended skill set.

The 1-day FMEA course is equivalent to 7 hours CPD.

We have welcomed delegates from a wide range of organisations to this course, including diverse manufacturing companies, software solutions providers, technology suppliers, and compliance consultants.

For those in the automotive industry, we offer further training on the guidelines for FMEA resulting from the publication of the AIAG and VDA handbook on our AIAG & VDA FMEA training course.

Previous delegates have highlighted the skill of the course tutor in understanding the needs of each group, offering relatable experiences and exercises, and providing everyone with a solid basis for considering how they can improve systems within their own organisations.

Comments at the end of the course have included:

- ‘I left with confidence and had the knowledge to complete an FMEA. 5 out of 5 for the course tutor, who was very knowledgeable and able to relate aspects of the course to real world examples’

- ‘The course has covered everything. Tailored to company needs, good case studies’

- ‘The course tutor was flexible and related the examples to our industry despite having a diverse group’

Customer reviews

Sumika Polymer Compounds (UK) Ltd|9th Jul, 2025

Sumika Polymer Compounds (UK) Ltd|8th Jul, 2025

Technipfmc Umbilicals Ltd|19th May, 2025

Endomagnetics Ltd|16th May, 2025

Incap Electronics UK Ltd|14th May, 2025

Cummins Inc|28th Apr, 2025

Sumitomo Electric Wiring Systems (Europe) Ltd|25th Apr, 2025

Truck Lite Europe Ltd|17th Apr, 2025

Luxfer Gas Cylinders|10th Mar, 2025

Sumika Polymer Compounds (UK) Ltd|7th Mar, 2025

Sumika Polymer Compounds (UK) Ltd|5th Mar, 2025

Macdermid Alpha Electronics Solutions (Hk Wentworth)|28th Feb, 2025